Choosing between concrete and steel stair structures

Richard McLane summarises the key elements of concrete vs steel stair structures.

Cost

When budgeting for a staircase, it is misleading to compare prices of concrete vs steel structures on paper. Besides the cost of the structure, you also need to consider finish, quality, accuracy, cladding and the balustrade itself.

Design

The person drawing a concrete staircase rarely thinks further than the layout. Finishes, cladding, balustrade and connections are usually not taken into account at this stage. Overlooking one or more of these elements is a classic mistake people make time and time again. The stair and balustrade must be fully detailed before you start building any part of it!

Open treads increase the flow of light

If you want a lightweight design, perhaps to let in more light, a steel structure will give you the look you want. You also have the option of choosing open treads to increase flow of light. Concrete structures are a popular choice for basement stairs, although can look clumsy in main living spaces. With any staircase, it’s important that the design works with the space available rather than take over it.

Liquid concrete is dependent upon many variables including temperature, consistency, mix and builder’s experience. Concrete structures can be difficult to cast with any accuracy. Steel is controllable through design and manufacturing methods to precision measurements.

On the edge

Clean edges – steel stringers are easy to install and clad

Think also about the edges of the staircase. Steel stringers can be clad in timber, painted or finished with specialist metal. Most concrete staircases are plastered or painted. They may need a stringer to cover the rough concrete, which is then finished in the same way as steel stringers.

Lighting

Bisca prefer to include lighting as part of the design. We will then liaise with electricians and lighting specialist as necessary.

Build Time

Builders spend a lot of time shuttering and reinforcing before they can cast a concrete stair. If time is tight, a steel structure will free your builder up to work on other areas of your project.

Bisca can usually split a staircase installation into two parts. This provides your site team with access early on in the project. We return to clad and finish when there is little danger of damage to materials.

Cladding

Both concrete and steel structures can be clad with a material of your choice. Cladding a staircase is an area where time is won or lost, and quality guaranteed or compromised.

Metal reinforcements make drilling into concrete risky

Drilling concrete structures for the purpose of cladding or balustrade fixing is not ideal. The process is time consuming and there is a real danger of hitting hidden reinforcing bars. Drilling into a metal bar could weaken the structural integrity of the whole staircase.

Steel is safer and easier to clad with stone because responsibility remains with the staircase specialist. Bisca will provide CAD data to the stone supplier to CNC. Cutting all components off site increases accuracy and reduces installation time. Electronic transfer of data reduces the risk of human error. Quality and finish of the installation is much improved.

A stonemason must template a concrete staircase on site. He then sends off the templates to get the treads made before returning to site to install. Fitting stone treads onto rough, inaccurate concrete structures is never straight forward. A high quality finish is usually compromised because drilling stone on site is risky. Cracking and flaking incidences are high, entailing removal, remaking and resetting

Handrail & Balustrade

Splitting the staircase and balustrade between suppliers may look like the cheapest option. In reality you will most likely end up paying more. There is also the hassle of coordinating several suppliers and resolving component design elements.

A staircase design from Bisca includes staircase and balustrade. Unfortunately this is not the case with some architects or builders. On many occasions Bisca have come across builder staircases where the builder has overlooked the need to fix a balustrade.

Inaccurately cast concrete stair with crumbling edges

Despite all this, it IS possible to retrofit a balustrade to all types of staircase. The best results are always obtained by using one supplier for staircase and balustrade. This route provides a jig for the balustrade and handrail in the workshop. Installation becomes a matter of reassembling and everything goes together on site as planned.

A balustrade supplier will have to template the stair before making and fitting. When he starts drilling into the concrete, he may face a similar situation to the stonemason. By this time though, he also has a layer of cladding to contend with.

In summary

Consulting a staircase designer is always going to give you the best results. Bisca consider the staircase and stair area from both form and functional aspects. We work as part of your project team to ensure the staircase becomes a seamless part of the build process.

Cutting out a specialist and handing architects plans to a builder or fabricator is not recommended. This route may limit your options and compromise the outcome.

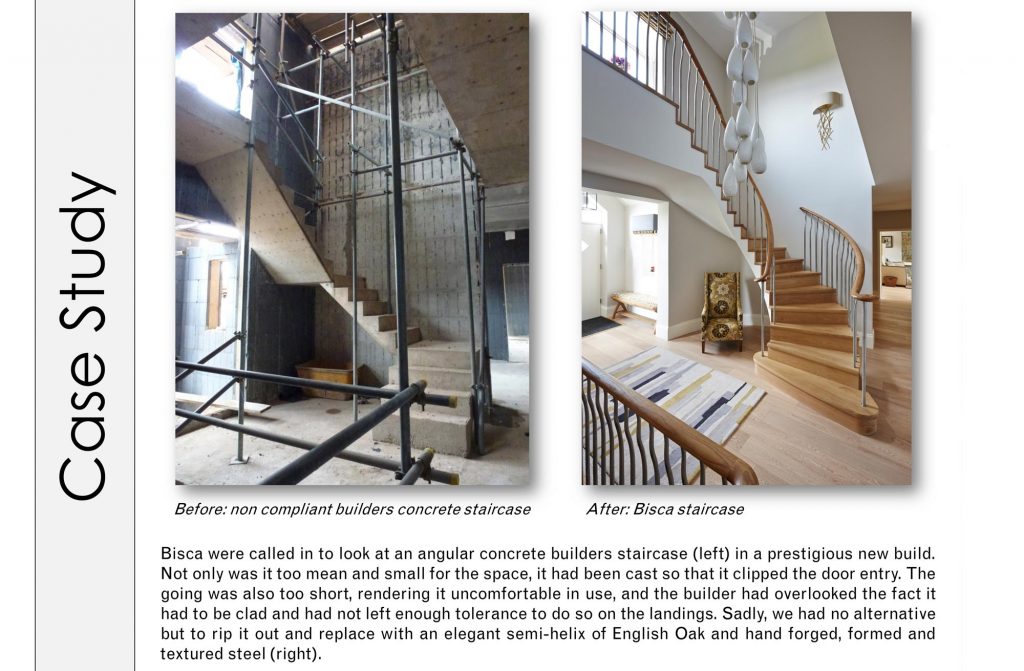

Faulty concrete staircase in new build had to be removed and replaced

For more information to help you decide between concrete vs steel stairs, please contact a member of our sales team.